Conference Schedule

Day1: August 1, 2019

Keynote Forum

Hiromi Nakano

Toyohashi University of Technology, Japan

Title: Photoluminescence- and electric- properties using a smart material of Li-(Nb,Ta)-Ti-O system

09:30-10:10

Biography

Hiromi Nakano is working as a Professor in the Department of Environmental and Life Sciences, and Cooperative Research Facility Center at Toyohashi University of Technology. She has completed her B S, M S and Dr. (Eng.) at Toyohashi University of Technology, Japan in 1981, 1983 and 2000, respectively. She joined Murata Manufacturing Co., Ltd. in 1983 and transferred to Ryukoku University in 1989. She joined the Cooperative Research Facility Center at Toyohashi University of Technology as an Associate Professor in 2009 and currently, she is working as a Professor and Presidential Advisor (Gender Equality). In 2010, she received the 64th CerSJ Award for Academic Achievements in ceramic science and technology. Her current interest is in the synthesis of new phosphors and characterization of ceramic materials using a transmission electron microscope to control the material properties and for the design of new materials.

Abstract

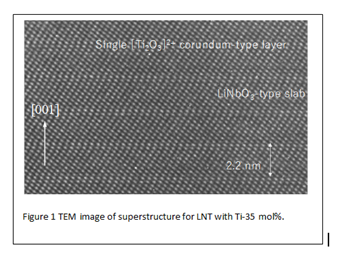

In the Li2O-M2O5-TiO2 system, Li1+x-yM1-x-3yTix+4yO3 (M = Nb, or Ta, 0.06£ x£ 0.33, 0£y£0.175 (LMT) forms with a superstructure, and this is known as a smart material. The superstructure is formed by periodical insertion of an intergrowth layer of corundum-type [Ti2O3]2+ in a matrix having a trigonal structure during the grain growth for a long sintering time. To apply this unique structure as a host material of phosphor, new phosphors have been investigated based on LMT or related structures made by a conventional electric furnace and millimeter-wave heating. Rare earth (RE3+: Eu, Er, Tb, Tm, or Dy) doped LMT phosphors with various emitted colors were successfully synthesized. Especially, we synthesized a new red phosphor based on the quaternary Li1+x (Ta1−zNbz)1−xTixO3 (LTNT, 0≤x≤0.25, 0≤ z≤1.0) solid solution. An Eu3+-doped LTNT has been prepared in a conventional electric furnace. Interestingly, a bright red emission due to the hypersensitive 5D0-7F2 transition in Eu3+ was observed under direct excitation of the 4f electron at 400 nm. In the LTNT host material, the most effective activator was found to be Eu ion and an internal quantum efficiency of 98% was achieved. We found that the high PL intensity was closely related to the polyhedral structure of the [Li (Eu) O12] in the host material. Still more, toward application of the unique qualities of an electro-ceramic, we fabricated oriented the solid solution for Nb system (LNT) balk ceramics by slip casting in a strong magnetic field of 12 T using various sizes of particles. Anisotropic electric properties were found along the c-axis, which were caused by a superstructure. We first clarified the mechanism showing that the anisotropic Qf value was caused by the anisotropic electron conductivity and the anisotropic bonding strength in the superstructure.

Armin Mehrabi

Florida International University, USA

Title: Development of smart materials and structures should anticipate evolution of structural systems and construction methods

10:10-10:50

Biography

Armin Mehrabi is an Associate Professor and ABC-UTC Director of Research in the Civil and Environmental Dept. of Florida International University (FIU). Before joining FIU, he served as the President of the Bridge Engineering Solutions specializing in inspection, evaluation, cable vibration and wind assessment, health monitoring, and rehabilitation of cable-supported bridges. He has published extensively on inspection and evaluation of bridges, laboratory testing and seismic analysis of masonry and infilled frames. His current research includes NDE, health monitoring and maintenance decision making, development of guidelines for ABC substructure selection, redundancy of steel box girder bridges, and precast prestressed pile splices.

Abstract

To facilitate application of smart materials and structures, one must consider the evolution of structural systems and construction methods. In other words, if we work on developing smart materials and structures having in mind current conventional structures and construction methods, by the time our product is ready, the structures and systems might have evolved to something different and the implementation might become obsolete. As an example, there is a substantial movement toward accelerated construction methods. One such approach deals with Accelerated Bridge Construction (ABC) that is defined as design, planning and construction methods to organize and arrange construction activities for new bridges, as well as repair, replacing and rehabilitating of existing bridges so that onsite construction time and mobility impacts are reduced, and public and worker’s safety is enhanced. The method relies heavily on using pre-fabricated modular bridge elements and assemblies that addresses some of the major drawbacks of the conventional bridge construction methods including delays to allow concrete curing, time constraints due to sequential construction, traffic interruptions and safety issues, compromise in quality for in situ activities, dependency on weather, etc. Recent tendencies toward automation and robotics also agrees well with the ABC notion. The inherent unique characteristics of ABC may also require unique materials and technologies for making the structure smart. This presentation attempts to discuss the characteristics of ABC and expectations on materials and technologies that would facilitate construction and maintenance of such structures in a smart manner.

Tracks

- Insight into Smart Materials and Technology | Headway of Smart Structures | Smart Control Systems in Industrial Applications | Advances in Material Science & Engineering | Architecture & Civil Engineering | Nanomaterials | Biomaterials | Physics & Chemistry of Smart Materials | Optical & Electronic Smart Materials | Artificial Intelligence-Automation Revolution

Location: Executive BoardRoom

Armin Mehrabi

Florida International University, USA

Chair

Mineo Hiramatsu

Meijo University, Japan

Co Chair

Mineo Hiramatsu

Meijo University, Japan

Title: 3D graphene network, synthesis, functionalization and applications

11:15-11:45

Biography

Mineo Hiramatsu has completed his PhD from Nagoya University and is a Full Professor in the Department of Electrical and Electronic Engineering, Meijo University, Japan. He served as the Director of Research Institute, Meijo University in 2017-2018. His main fields of research are plasma diagnostics and plasma processing for the synthesis of thin films and nanostructured materials. Author of more than 150 scientific papers and patents on plasma processes for materials science. He served as a Chairman and Member of organizing and scientific committees of international conferences on plasma chemistry and plasma processing. He was awarded the Japan Society of Applied Physics Fellow in 2017

Abstract

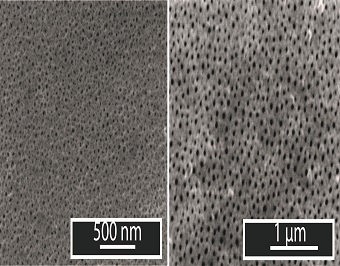

3-dimensional (3D) graphene network with large surface area could be promising material as a platform for electrochemical and bio applications. This kind of carbon nanostructure is called as carbon nanowalls (CNWs), carbon nanoflakes, carbon nanosheets, graphene nanosheets, and graphene nanowalls. CNWs and similar materials are basically self-supported network of few-layer graphenes standing almost vertically on the substrate to form 3D structure. CNWs can be synthesized by plasma-enhanced chemical vapor deposition (PECVD) on heated substrates (600-800ËšC) employing methane and hydrogen mixtures. The height of CNWs increases almost linearly with the growth period, while the thickness of each sheet and interspaces between adjacent sheets are almost constant. The maze-like architecture of CNWs with large-surface-area graphene planes would be useful as electrodes for energy storage devices and scaffold for cell culturing. Especially, combined with surface functionalization including surface termination and decoration with nanoparticles and biomolecules, CNWs can be suitable as platform in electrochemical and biosensing applications. We have carried out CNW growth using several PECVD techniques. Moreover, graphene surface was decorated with Pt nanoparticles by the reduction of chloroplatinic acid. We also report the performances of hydrogen peroxide sensor and fuel cell, where CNW electrode was used. Electrochemical experiments demonstrate that CNWs offer great promise for providing a new class of nanostructured electrodes for electrochemical sensing, biosensing and energy conversion applications.

Aiman Darwiche

Nova Southeastern University, USA

Title: Machine learning techniques to predict the characteristics of zeolite

11:45-12:15

Biography

Aiman Darwiche has completed his PhD from Nova Southeastern University in 2018. He is the Co-founder and Chief Data Scientist at Compu-House, a startup that emphasizes on building prediction models for life threatening health conditions before their occurrences. Besides, he teaches undergraduate courses at Northern Kentucky University. He has several papers.

Abstract

Machine learning can predict characteristics of material with high accuracy rates. Using Random Forest, we built a prediction model that depends on the geometric features, such as local geometry, structure, and porosity of the material, to predict the bulk and shear moduli of material with a high accuracy. The prediction model will be used on zeolites to predict the elastic response but can be extended to other materials. The proposed model is evaluated by comparing its predictive accuracy to those of extant methods.

Katerina Dedkova

VSB Technical University of Ostrava, Czech Republic

Title: Influence of chemical and electrochemical surface treatment of ECAP titanium on resulting corrosion properties and wettability

12:15-12:45

Biography

Katerina Dedkova has completed her PhD from VSB-Technical University of Ostrava. She is the Researcher at Center of Advanced Innovative Technollogies. She has published more than 14 papers in reputed journals and has been serving as a Rewiever of repute journals. Her research interest include biocompatible materials and nanocomposite materials.

Abstract

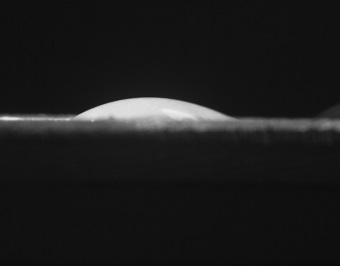

ECAP titanium of lower grades with extra fine grains may be used for manufacturing of highly loaded implant or their parts and presents excelent replacement of strandartly used Ti-6Al-4V alloy. This type of material aslo showes excelent corrosion properties ang high level of biocompatibility, which can be even impoved by different surface treatment. This paper deals with possibility oxidic anodization as a method of creation highly organised nanostructures on implant surface and further chemical treatment of anodized layer in acid/alkaline solutions. It was proved that chemical treatment increases content of specific ions in anodized structure, which will leads into more effective osteointegration process while not affecting its of corrosion properties, which was tested by potentiodynamic polarization methods in artificial isotonic physiological solution according ASTM standards for implants. On the other hand chemical treatment positively affects wettabilility resp. surface energy of studied samples. Many previous studies focused on osteointegration process confirmed that lower values of contact angle directly corelate with effectivity of ossteointegration process and a relation between preferred induced type of organic tissue and implants surface energy has been previously published. Presented procedures of surface treatments shows promising results and might find its use in commertial implants manufacturing

Ahmad Fakih

Friedrich Kocks GmbH & Co KG, Germany

Title: Microstructure simulator to predict grain formation during thermo-mechanical processing of long products

13:30-14:00

Biography

Master of Science in Mechanical Engineering with the focus on material science at Ruhr-University-Bochum. Present job title: Manager Development, Process and Consulting. Research interest: see recent publication, measuring surface defects, microstructure simulations.

Abstract

Today, temperature-controlled rolling is a well-known application in rolling mills to improve the technological properties of the materials in accordance with the market requirements. In comparison to standard operation procedures, this processing especially requires a reliable and holistic concept in daily operation. It becomes even more important, when special demands need to be met especially with fast reaction times concerning first results. In order to fulfill such demands successfully without the necessity of extensive test trials, an overall integrated concept for thermo-mechanical rolling of long products has been developed. Special attention is placed on a recently developed microstructure simulator. It is a semi-empirical model for temperature and process calculation predicting the resulting grain sizes, microstructure distribution and mechanical properties. Especially with its customized, flexible database, which can be individually extended, the producers are enabled to react fast to market movements and specific requirements. The simulation software has its focus on the specific microstructure evolution of long products e.g. bar, wire rod and tubes. The simulation model features an analytic model to calculate strain distribution for different reduction configurations and varieties of technological parameters, e.g. temperature, speed, pass geometry for standard mill configurations as well as for the 3-roll technology. Based on the distribution of the strain modification and temperatures over the cross-section of the rolled product, the microstructure simulation is carried out to get a realistic image of the final obtained micro-structural formation.

Matthias Schuck

Friedrich Kocks GmbH & Co KG, Germany

Title: Results of using laser triangulation for measuring surface defects in long products

14:00-14:30

Biography

Education: Dipl.-Ing. of RWTH Aachen (Rheinisch-Westfälische Technische Hochschule)

Present Job Title: Manager Process Engineering

Abstract

Alongside profile measurement the technology of laser triangulation is increasingly used to detect surface defects. Such defects can either be of dimensional nature or result from the rolling or sometimes casting process. In a first part, the presentation describes the first-time installation of such a laser triangulation system in a combined long product rolling mill and then goes on to introduce the operative software as well as to give examples of applications.The second part of the presentation illustrates the idea of using the potential of artificial intelligence with regard to detection systems for material defects.

Alena Michalcova

University of Chemistry and Technology, Czech Republic

Title: Self-Healing in rapidly solidified aluminium alloys

14:30-15:00

Biography

Alena Michalcová has completed her PhD from University of Chemistry and Technology in Prague and Postdoc Fellowship in Max-Planck Institute für Eisenforschung in Düsseldorf, Germany. She has published morethan 58 papers in reputed journals.

Abstract

Rapid solidification of alloys can be preformed e.g. by melt spinning method. This process leads to several changes in the microstructure, the main are increase of solubility of allying elements, microstructure refinement and formation of metastable phases such as quasicrystals. These microstructural features have prommising potential for self-healing behaviour of the material. Decomposition of supersaturated solid solution can lead to precipitation healing mechanism that was already proven in underaged aluminium alloy. Decomposition of quasicrystals can also cause closing of the crack in the alloy. The self-healing behaviour in the Al-Cr-Fe alloy was observed in this work. The alloy was studied by LM, SEM and TEM. Correlative SEM/AFM microscopy was also performed.

Sergio Ricardo de Lazaro

State University of Ponta Grossa, Brazil

Title: A DFT investigation on multiferroism and magnetic coupling in NiBO3 materials

15:00-15:30

Biography

Sergio Ricardo de Lazaro has his expertise in silico experiments, more specifically in solid state chemistry, defects, electronic structure, optical property, magnetism and surface. The main tool used is Density Functional Theory from CRYSTAL code. He proposes a new approach for properties in multiferroic materials and morphology analyses. He is a full Professor at State University of Ponta Grossa acting as a Referee in PCCP Physical Chemistry Chemical Physics, Journal of Alloys and Compounds, The Journal of Physical Chemistry and others.

Abstract

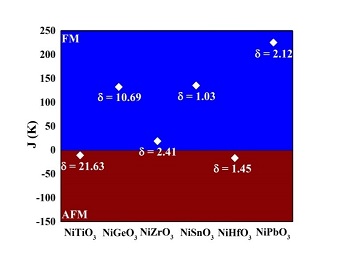

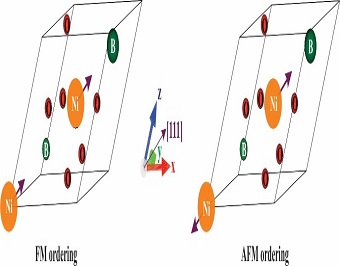

In technological field, the emergent materials are known as smart materials because present high sensibility and the ability to adapt to external stimuli. Among the smart materials stand out the multiferroic (MF) materials. The multiferroism effect is associated to the coexistence and coupling between magnetic ordering and ferroelectricity in the same crystalline phase. The most common form of multiferroism is called magnetoelectric (ME) coupling. Some example of MF materials are: BiFeO3 (BFO) which shows a unique set of electronic, optical, magnetic and ferroelectric properties and that can be easily obtained through an epitaxial growing on SrTiO3 substrates; the present abstract aim to show of new MF materials based on PbNiO3 (PNO) materials with R3c structure considering an occupation in A and B sites. Therefore, the A sites were occupied by Ni atoms while the B sites were occupied by Ti, Ge, Zr, Sn and Hf atoms, respectively. The calculation level was choose as Density Functional Theory (DFT) at set B3LYP hybrid functional; employed in CRYSTAL09 software. For all materials investigated as ferromagnetic (FM) as antiferromagnetic (AFM) ordering were simulated. For NiTiO, the AFM ordering was calculated as more stable, in agreement to experimental and other theoretical results. Similar result was calculated for NiHfO, i.e., an AFM ordering. However, the FM ordering was found for NiGeO, NiZrO, NiSnO and NiPbO materials suggesting a relation between structural regularity and magnetic phase. Along the y axis was not observed the formation of charge path between the atomic layers due to proximity between atoms. In case of z direction, discreet charge paths and charge polarization were observed while the higher polarization was exhibited along x direction once superiors charge paths and high polarization are formed. Thus, the ferroelectric properties in R3c materials are preferentially oriented in x direction in crystalline structure as expected for an anisotropic ferroelectric. The multiferroic effect was determined by analysis of magnetic and ferroelectric properties along x, y and z direction of unit cell; it was noted that the magnetic property is oriented along z axis, while the ferroelectric property is oriented preferentially along x axis. Hence, the coupling between both properties evidences a multiferroism effect on NiBO3 (B=Ti, Ge, Zr, Sn, Hf and Pb) materials.